Material

A material is

a substance or mixture of

substances that constitutes an object. Materials can be pure or impure, living

or non-living matter. Materials can be classified based on their physical and chemical properties, or

on their geological origin or biological function. Materials

science is the study of materials and their applications.

Raw materials can be processed in different ways to

influence their properties, by purification, shaping or the introduction of

other materials. New materials can be produced from raw materials by synthesis.

Engineering Materials

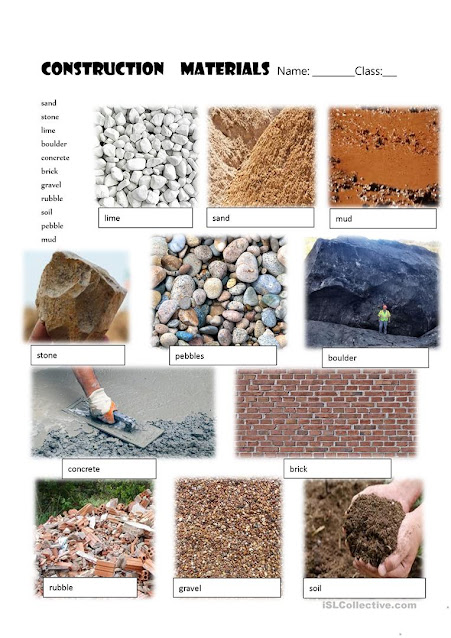

Any

materials that are used as raw material for any sort of construction or

manufacturing in an organized way of engineering application are known as

Engineering Materials.

For example, the Mobile or the Refrigerator we use, are manufactured through controlled engineering processes. These

gadgets make use of materials like Silica, glass, copper, aluminium, tin, etc.

in their fabrication. Civil construction works like building, bridges, dams, roads, pavements are carried out with raw

materials like steel, stone, chips, cement, clay, paint, bars, etc

Properties of

Engineering Material:

A quality that define a specific

characteristic of a material is as a property. The properties of a material

provide a basis for predicting its behavior under various conditions. They are

the tools the engineer uses to solve his material problems .Some of the most important properties of engineering

material are:

1.Physical

Properties:Size,Shape,density,porosity,structure.

2.Mechanical properties: Strength, elasticity, plasticity, stiffness,ductility, malleability, resilience, creep.

3.Chemical

Properties: Corrosion, resistance, acidity, alkalinity, chemical, composition.

4.Thermal

Properties:Specific heat,thermal expansion,conductivity.

5.Magnetic Properties: Conductivity,dielectric permittivity,dielectric strength.

6.Electrical Properties:Conductivity,dielectric permitivity, dielectric strength.

Important Properties

of Engineering Material:

Most

Properties of Engineering Materials must be evaluated entirely by experiment.

Certain specific conditions are applied and the corresponding properties are measured.Experiments for determining

properties of engineering materials are usually called tests.Tests may provide

properties for use in design or information on the quality of a material.The

procedures are usually standardized because if identical procedures are always

followed the results of a number of test

may be compared with some assurance.Much of the standardization is done by the

national organization set up in each country to improved the use or materials

in engineering constructions and also in industries.Some of these organizations

are BSI(British Standard Institute),ASTM(American Society of Testing

Materials),AASHO(American Association of State Highway Official),ACL(American

Concert Institute).Each organization gives standard test methods of all kinds

in addition to standard specifications for materials and standard definitions

of terms.

The

following are the very important

properties of engineering materials :

(1 Strength: It is the

property of material that represents its ability to resist internal forces or stresses. The

three basic strengths of a material, the

type of force to which the materials is to be subject, must be known. As for

example the compressive and tensile strength of structural steel are nearly

equal. Whereas cast iron can take more compression and it is weak in

tension.Similarly, concrete is very strong in compression but very week in

tension.

(2 Elasticity: It is a

property of a material which allows it

to return to its original shape and size after the load to which it is

subjected is released.This is a very important property of engineering

materials. The strain for a given of load during the unloading process is equal

to the strain for the same value of load during the loading process. A limiting value of load will be found at which the

strain does completely disappear with the removal of the load.The value of

stress corresponding to this load is called the Elastic Limit.

(3 Plasticity: plasticity is the opposite property of

elasticity. A perfectly plastic material does not return to its original shape and size when the load causing

deformation is remove.Lead is an example of plastic material.

(4 Malleability: This

property permits plastic deformation of

a material when subjected to compression . materials that can be hammered into

the thin sheets are malleable materials .

(5 Brittleness: The

opposite property of malleability is brittleness. Cast iron is an example of brittle material.

(6 Stiffness : The term

stiffness designates the resistance of a materials to deformation in the

elastic range .Stiffness of ductile material is measured by the modules of

elasticity.

(7 Ductility: Ductility

indicates the ability of a material to deform in the plastic without breaking.

No accurate measure of ductility

exists.For comparative purposes. However, ductility is usually defined by the

percentage elongation of a tensile specimen at fracture for a specified length.

(8 Toughness:This

property matures the ability to absorb to release energy in the plastic range.

(9 Fatiguethe: Certain

materials are very often subjected to repeated stress. The term fatigue (fatigue strength) of a materials is used to indicate its strength in

resisting repeated stress.

(1 Hardness:The term hardness.

When used as a technological property of materials .Is primarily associated

with the surface .An appropriate definition of hardness is the resistance of a material to permanent

deformation of its surface. This deformation may be in the form of scratching mechanical wear or cutting.

(1 Resilience:The resilience

of a material is its ability to absorb energy in the elastic range. It is measured by the energy per unit volume

required to stress a material in tension form zero stress to the proportional

limit.

(1 Creep:In many

applications. Engineering materials are required to sustain steady loads for

long periods of time R.C.C(reinforced cement concrete)beams,columns.etc. Under

such conditions the material may continue to deform until its usefulness is serially

impaired . Such time dependent deformations may be almost imperceptible but over

the life time of a material or structure they can grow large and even result in

final fracture without any increase in load.

Selection

of engineering materials: selection of materials for engineering applications

depends first upon their properties in relation to intended use. The engineer should be alert for new materials

that may be developed but he should also keep his mind receptive to possible

new ways of using existing materials.

The

next important considerations are economy

and availability. Preference should always be given to the locally

available materials. Sometimes, a material must be selected even though

inferior properties. because the right material is not locally available or too

expensive.

0 Comments